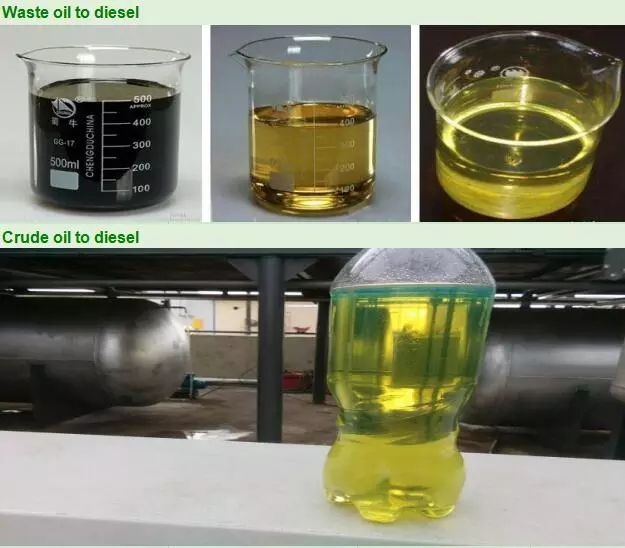

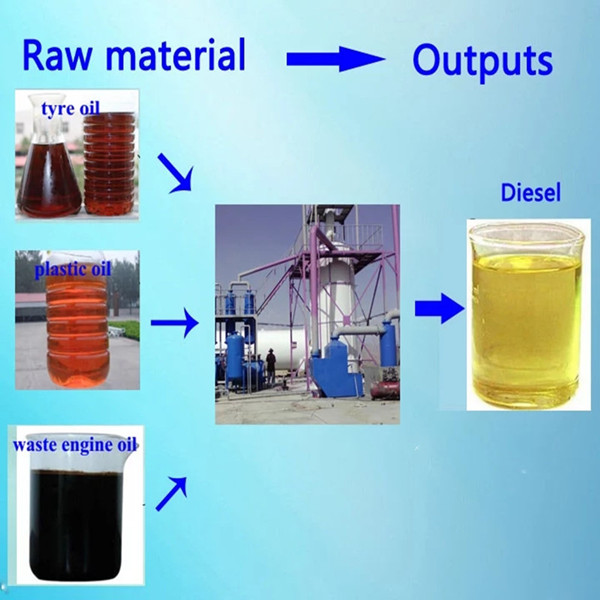

The Latest technology 5-30T oil distilaltion machine to diesel is amazing technical solution for different waste oil such as waste engine oil, pyrolysis oil, sludge oil, mud oil,very thick dirty impurities oil .

This technology is mainly to use steam generator to make steam which can have effection with oil gas to reduce pressure to vacuum level. then when the operation is going on, diesel can be produced at 300℃ -550℃ ,however,now the highest temperature is 300℃ -380℃ .in this way oil quality will be highly improved and also fuel can be used less.

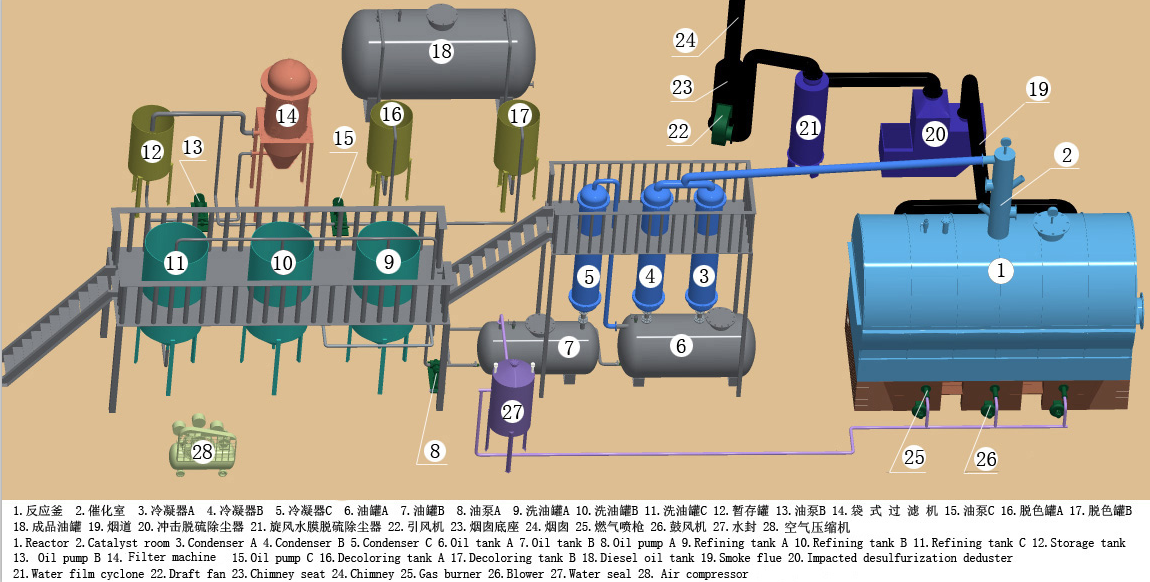

Complete System

Reaction tank:crude petroleum oil will be pumped into this tank from the primary filter

Heating system: by burning coal or fuel we can work the oil temperature up to setting value.This system equips with insulation system as well.

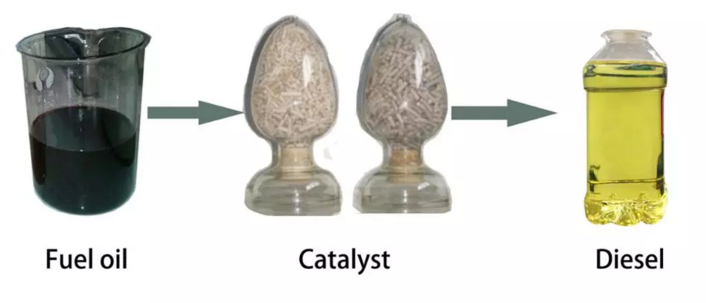

Catalytic system: crude petroleum oil reaches the expected temperature,via catalytic effect,and the gaseous hydrocarbons become gasoline and diesel compositions.

Cooling system: after the catalytic effect,the gasoline and diesel compositions will be condensed into liquid materials.

Temperature control system: to make sure the crude petroleum oil transformed into gasoline and diesel.When the crude oil is dried by distillation,it can stop heating timely.

Tail gas handling system: through tail gas system,a small amount of unliquefied gas left can meet emission standards.

Item | Detail | |||

Type | JZ-05 | JZ-08 | JZ-10 | JZ-15 |

Raw Material | Waste oil | Waste oil | Waste oil | Waste oil |

Capacity/Batch | 5T | 8T | 10T | 15T |

Working | Batch Type | Batch Type | Batch Type | Batch Type |

Covering Area | 150sq | 160sq | 180sq | 200sq |

Worker | 2-3 | 2-3 | 2-3 | 2-3 |

Reactor Size | D1600*L4000 | D1800*L4000 | D2000*L4400 | D2200*L5500 |

Noise | ≤85dB | ≤85dB | ≤85dB | ≤85dB |

Cooling Type | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

Weight | 21t | 23t | 24t | 26t |

Running Time | 40-44h | 40-44h | 40-44h | 40-44h |

Fuel | Coal,Wood,Oil,Gas | Coal,Wood,Oil,Gas | Coal,Wood,Oil,Gas | Coal,Wood,Oil,Gas |

Catalyst | Needed | Needed | Needed | Needed |

Remark | It can be customized according to customer’s actual needs | |||

Material Balance Sheet

No. | End Production Name | Yield | Usage |

1 | Diesel | 73% | * Used for Engine Fuel |

2 | Gasoline | 12% | * Used for Engine Fuel |

3 | Residue Oil | 9% | * Feeding into Pyrolysis Machine for Pyrolysis * Used as heating fuel for Distillation machine |

4 | Non-Condensible Gas | 3% | * Recycle as Heating fuel after treated by Gas-treatment System |

5 | Other | 3% | * Water and impurity 2% * Loss 1% |