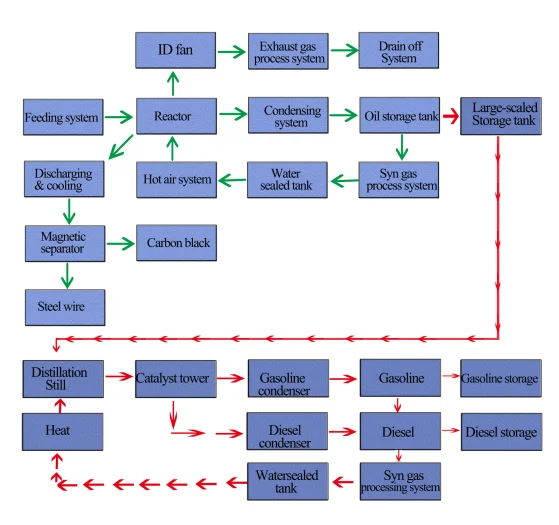

Waste tyre crushing system →Constant temperature heating system →Continuous pyrolysis system →Carbon black production system →Gas purification system →Flue gas purification system →Control system →Oil distillation system →Diesel

Fully continuous waste tire/tyre&plastic pyrolysis plant adopts automatic feeding and discharge system with sealed solution; Circulating hot air supply heat to reactor, instead of burner flame heat directly; Q345 steel plate as material for rotating reactor, 8-10 years' working life. Oil output can reach 50%-55%( 60-95% for plastic). Capacity from 15T to 100T. After couple of hours, Syn gas from pyrolysis generated and burn in hot air system to supply energy to pyrolysis procedure. Pyrolysis oil cleaned in gas treatment system and then inserted to oil distillation system, which can make it be clean diesel and gasoline. Carbon black and steel wire will be separated and collected at the end of the system. This is the most advanced technology, energy saving and environmental friendly.

Specification

| Technical data | Continuous Tyre Pyrolysis Plant |

| Capacity | 30 tons/day, 50tons/day |

| Voltage | 380V/50hz |

| Electric power consumption | 11KW |

| Alternative fuel type for startup | Natural gas/heavy fuel oil |

| Heavy fuel oil | 800kg/Day |

| Lead time | 45Days |

| Plant minimum area occupied | 32 meters length, 15 meters width, 10 meters height |

| Condensation assembly weight | 7±5% tons |

| Pyrolysis reactor weight | 40±5% tons |

| Pyrolysis reactor diameter | 1700 mm |

| Maximum temperature of oil gas | 200 ℃ |

| Cooling media type and its temperature at the inlet of the HX | Cooling water no more than 40 ℃ |

| Required utilities | Initial cooling water supply Electric power supply |

Working Process

Plant advantage

1) widely usage

Can be used for tyre 5-10cm,plastic,rubber ,oil sludge, cooking waste ,live waste, oil sand ,oily soild

2) static pyrolysis ,getting higher quality oil, less dust in oil

3) large capacity 24 hours produce 40-60 Ton material

4) continuous pyrolysis, no need cooling reactor, saving fuel, saving working time

5) The plant can working 25dyas*24hours without stop, fully continuous

6) Continuous feeding without stop ,saving labour and saving time

7) Continuous slag out without stop ,saving working time .

8) Non-liquid gas can be reused to support heating for heating reactor , saving fuel energy

9) good pressure tightness, safe

Final product

----- Diesel 85-90% Since tire/plastic pyrolysis oil is a kind of special oil, which has big difference with petroleum from underground mining. Of course diesel made from tire/plastic pyrolysis oil is little different from petro-diesel. But through our experiences and feedbacks from our customers that this diesel product can be directly used in diesel burners, generators, farm machinery and heavy industrial equipments. Only when used in modern diesel engines, it would be better mixed with petro-diesel in 30-50%. But if your raw material is waste engine oil, then no need to worry. Waste engine oil after refining is the same as standard diesel, which can be used for any applications same as petro-diesel. |  |

----- Asphalt 10-15% Asphalt is a byproduct in the oil refining process. But this asphalt product can be directly sold to asphalt plant or Construction Company. |  |