Final Products:Pyrolysis Oil,Carbon Black,Steel wire(for tire),Syngas

Fuels:Diesel,LPG,Natural Gas,Syngas,Wood,Coal

Land Required:300m2

Worker Required:4-6 workers,two shifts

Cooling:Water Cooling

|

1)The raw material for pyrolysis machine

NO. | Raw material | Note |

1 | Waste tyre | All kinds tyre ok |

2 | Waste plastic | PE is best |

3 | Waste rubber | Waste shoe sole, waste cable sheath |

4 | oil sludge | oil tank sediment etc... |

| ||

The machine is universal, Just processing a little different. Our engineer will training you as your raw material use. | ||

2) The machine capacity working power

NO. | Model* Reactor thickness | Capacity | Note | Working power |

1 | 2200-6000mm*14mm | 5tons/batch | 2 days 3 batches | 14kw |

2 | 2200-6600mm*16mm | 6tons/batch | 2 days 3 batches | 14kw |

3 | 2600-6000mm*16mm | 8tons/batch | 1 day 1 batch | 20kw |

4 | 2600-6600mm*16mm | 9tons/batch | 1 day 1 batch | 20kw |

5 | 2800-6000mm*16mm | 10 Ton/batch | 1 day 1 batch | 20kw |

6 | 2800-6600mm*16mm | 12 Ton/batch | 1 day 1 batch | 20kw |

7 | 2800-7500mm*18mm | 15 Ton/batch | 1 day 1 batch | 25kw |

The advantage compare with other supplier: We can discharge carbon black immediately after finish heating, Can save the cooling time around 6-8 hours, the efficiency rise up more. | ||||

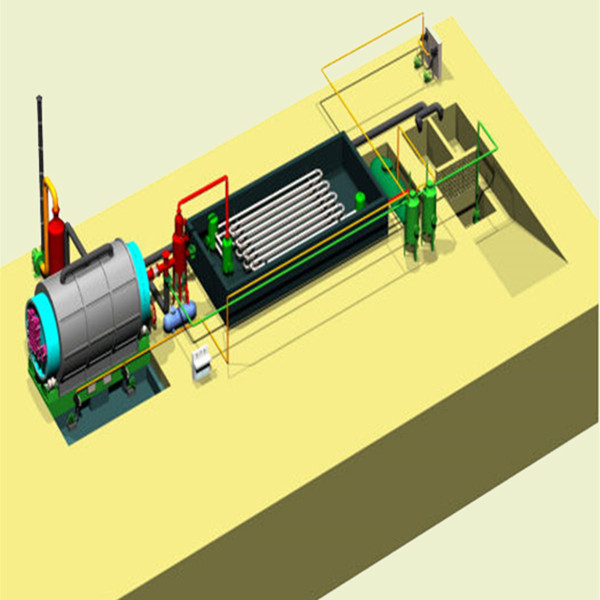

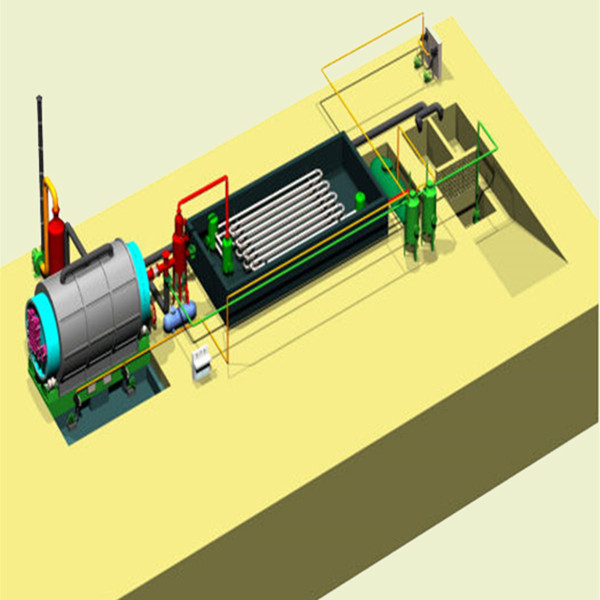

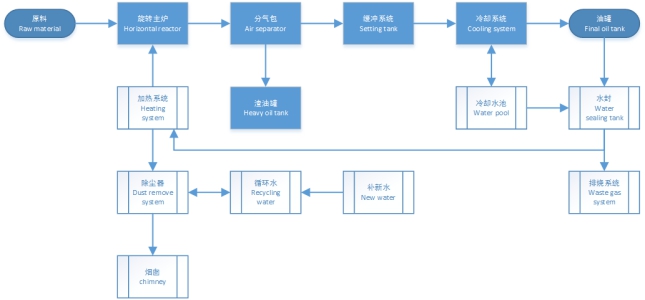

3) Process flow diagram:

4) Running machine video link

5) Fuel can be used:

NO. | Fuel | Burning auxiliary tool |

1 | Coal | fire bar |

2 | Oil(pyrolysis oil, diesel oil etc..) | oil burner |

3 | Natural gas | gas burner |

4 | Carbon black pellet | We can supply carbon make pellet machine |

6) The processing time(for example raw material is tyre)

NO. | Model* Reactor thickness | Loading time | Processing time | Cooling time | Discharge time |

1 | 2200-6000mm*14mm | 1 hours | 7 hours | no need cooling | 1 hour |

2 | 2200-6600mm*16mm | ||||

3 | 2600-6000mm*16mm | 2 hours | 10 hours | no need cooling | 1.5 hours |

4 | 2600-6600mm*16mm | ||||

5 | 2800-6000mm*16mm | 3 hours | 12 hours | no need cooling | 1.5 hours |

6 | 2800-6600mm*16mm | ||||

7 | 2800-7500mm*18mm | 3 hours | 14 hours | no need cooling | 2 hours |

The advantage compare with other supplier: We can discharge carbon black immediately after finish heating, Can save the cooling time around 6-8 hours, the efficiency rise up more. | |||||

7) End product percentage and useage (for example:the raw material is waste tyre)

NO. | Name | Percentage | Usage |

1 | Tyre oil | 45% | * can be sell directly. * make diesel and gasoline by use oil distillation machine. * can be as fuel for heating pyrolysis machine or distillation machine. |

2 | Carbon black | 30% | * can be sell directly. * make fine carbon by use carbon black refining machine. * make pellet by use carbon make pellet machine. |

3 | Steel wire | 15-20% | *can be sell directly. * make steel bloom by use hydraulic press-packing |

4 | Non-condensable gas | 5% | * can be as fuel burn by use gas burn system(we supply gas burner free.) *extra gas also be storage as fuel for other heati |

8)Tyre oil testing report by SGS

9)Packing containers:

NO | Model*Reactor thickness | Packing |

1 | 2200-6000mm*14mm | 2*40HQ |

2 | 2200-6600mm*16mm | |

3 | 2600-6000mm*16mm | 1*40FR(open container) 1*40HQ |

4 | 2600-6600mm*16mm | |

5 | 2800-6000mm*16mm | |

6 | 2800-6600mm*16mm | |

7 | 2800*7500mm*18mm | |

| ||

10)motor need

NO. | Name | Amount | power | photo |

1 | Speed reducer | 1 set | 5.5kw / 4kw |

|

2 | Draft fan | 1 | 7.5kw / 4kw |

|

3 | blowers | 4 | 1kw for 4 blowers |

|

4 | Water pump | 2 | 3kw for 2 pumps |

|

5 | Oil pump | 1 | 1.5kw |

|

6 | Discharge machine | 1 | 3kw |

|

7 | Auto feeder | 1 | 5kw |

|

8 | Elevator | 1 | 3kw |

|

11) The machine installation(charge and time)

We will give the foundation drawings to buyer after make the order .we will send engineer when buyer get the machine. The engineer mainly install the machine and training your workers.

We pay engineer salary when installation. Buyer book ticket , supply food and accommodation to engineer. Installation time about 25 days. At most 30days. According the work efficiency.

12) The machine cover area:

The machine itself cover 300-400 square meters(length 20-30M ; Width 10M, height 6-8M)

Add raw material stay, carbon black stay, big oil tank zone ,workers rest room and simple office. At least 600-800square meters.

13) How many workers need operate machine:

1-2 workers if use auto feeding system.

3-4workers if use manual feeding.

14) Service :

We warranty the complete machine 2 years. The maintance is all life.

We use the Q245R and Q345R Special boiler steel plate, can bear 700℃ temperature when pyrolysis.

When machine have some problem (but wearing parts) if operate is right, we send engineer to buyer site maintance, it is free within 2 years.