Raw material :

1.Waste rubber tire, waste plastic, waste rubber products, etc.

2.Industrial mixed waste plastic, allowing dozens of waste existing at the same time (such as PP, PE, PVC mix together etc).

3.Waste oil:waste diesel, lube oil, engine oil, waste oil residue, mazut, tar oil, wax oil, waste crude oil etc.

4.Waste cable cover.

5.Waste PMMA(methyl methacrylate)rebirth.

6.Drainage oil, acid oil.

Working process

1.Put raw material into reactor by auto feeder, then close feeding door.

2.Make reactor rotate clockwise 0.4r/min.

3.Burned the fuel material (coal, wood, natural gas or oil) in the furnace. Reactor will be slowly heated, when the temperature reach around 80℃, oil gas will come out.

4.The oil gas will through catalyst chamber and condenser pipe,getting to the water oil separator.Some water of the tyres will sink to the bottom,and the oil will float on the water.Then about 60% oil will flow to the first oil tank.

5.The other gas will go to cooling system,it through slowly and have a good recycle in horizontal condenser.Then we will get about 40% oil flow to the second oil tank.

6.Some incondensable gas which can’t cool down will be get to the anti-back fire device,then it will be recycled to the heating system,used to heat reactor which can save your energy. Only the first 2 hours use energy for heating. After the first 2 hours mainly use gas, little energy is OK.

7.When the temperature get to about 300℃,there are no tyre in the reactor,and the oil will come out over.At this time,we will stop heating,when the temperature fall down to 100℃- 150℃. Then open the door of carbon black discharging system,and make it rotate anticlockwise, the carbon black will get to the pool automatically.

8. After discharging carbon black,open the vacuum pump device.Release the air inside the furnace,avoiding to catch fire.

9.When the temperature deduce to about 50℃, we can opened the door of reactor take steel wire out.

10. And then you can start the next batch.

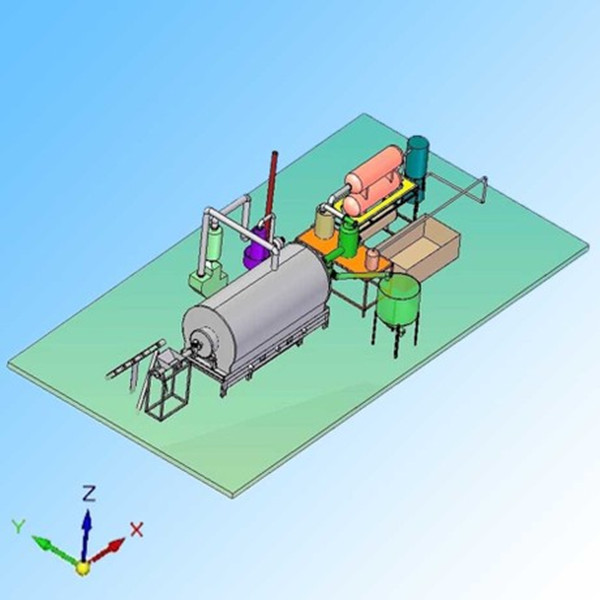

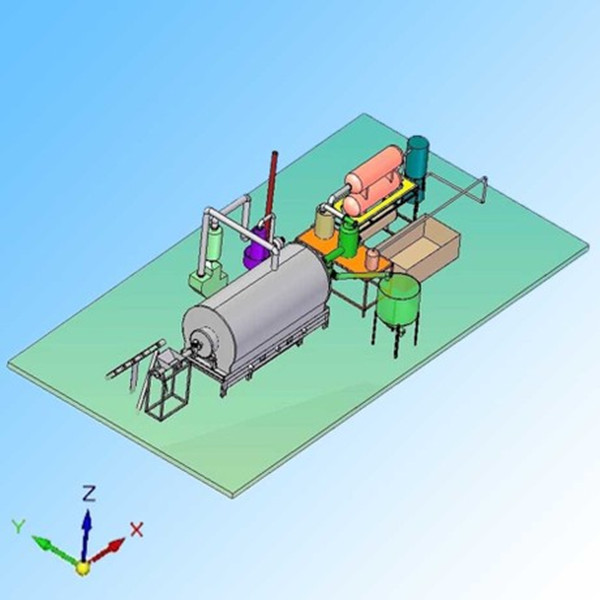

Complete line can be divided into five parts:

1)- The Heating system:

Two heating rooms and indirect heating .

2)- The Cooling system:

4 new design condensers to convert the oil gas into oil.

3)- The Waste gas purifying system :

Its function is to remove the acids, bad smell and dust from the waste gas, so the gas will be

more clean and environmental friendly.

4)- The Smoke purifying system :

Its function is to remove the acids,bad smell and dust from the smoke, so the smoke into the air

will be clean and no pollution

5)- The Carbon black discharging system :

We adopt the whole sealed automatic discharging system to ensure no carbon black flying

out,so the whole process is no pollution at all.

Features

1)There is no need to remove impurities such as silt, water, iron wire.

2)Put the waste plastic directly into the high temperature cracking processor at normal pressure to heat and catalyze, to distill the gas-state oil.

3)When it flows through the condenser, the liquefiable portion is condensed into mixed oil.

4)The portion that can not be liquefiable is burnt beneath the processor through gas burning system. Firstly, the condensed mixed oil is put into distilled processor to heat, through catalyst and reforming process, gas-state oil is distilled from the mixed oil. Secondly, the gas state oil flows into the condenser to distil the crude fuel oil. Then, qualified fuel oil is sorted out by means of precipitating and filtration and adding sorts of additive.

The Output Percentage and Usage (tyre for example)