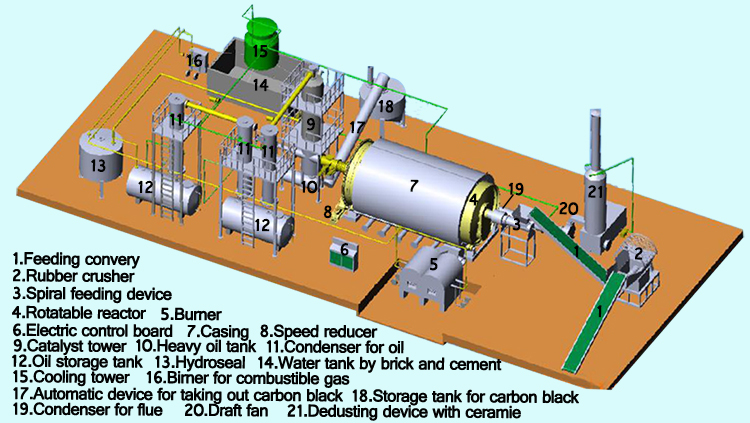

working process

feed raw material (belt conveyor)-- heat(reactor)-- oil gas comes into being-- impurity deposits (gasseparate)--heavy oil deposiys(depositing tank)-- cooling down(cooling pool)--get light oil(light oil tank)--flammable gas reheat reactor--take out carbon black(screw conveyor)

3D drawing flow chart and working processing

Introduction of main part

Pyrolysis Reactor | 1. Made by Q345R boiler plate. Also can choose SS310, 310S+Q345R 2. Auto-welding both inside and outside 3. With rock wool insulation board |

Auto-feeder | 1. 50 ton hydraulic pressure 2. Can feed all types of materials 3. Save labor and save time

|

Catalyst chamber | 1. improve oil yield and oil quality 2. Reduce the speed of oil gas so that it can be better cooled |

Oil-water separator | 1. Separate oil and water 2. Collect heavy oil 3. Water sealing design keep safety |

Condenser | 1. The oil gas is cooled separately by small pipes inside condenser 2. Light oil is collected here |

Vacuum device | Keep tirepyrolysis recycling machine running under normal pressure |

Anti-back fire device | 1. Recycle residual gas to furnace as fuel 2. Water sealing design prevent tempering |

Dust removal device | Dispose of flue gas caused by using coal, wood, oil or natural gas. |

Working process | |||||

Loading tyres into reactor with auto-feeder | Preheating | Oil output | Cooling down | Carbon black discharging | Steel wire discharging |

2 hours | 2 hours | 12 hours | 2 hours | 1 hour | 1 hour |

main technical characteristics

1. High oil output rate 45%--55% with special catalyst formula and high tech .

2. Rapid condensers and large cooling area,assure you get much more and higher quality oil.

diversiform cooling system can be choose according to client's willingness

3. Dust-removing device -four levels dust processing system make sure no any population and the output smoking is the spray .more environmental protection.

4. Double tail-gas recycling and burning system, saving energy.

5. Q245R boiler plate, high temperature resistance, thickness reaches 14mm—16mm,guarantee 4-7 years service lives. and optional plate is Q345R

6. OptionalAuto feeder and carbon black discharge elevator, high automation, saving time and labors.

7. Eco-friendly and no any population, environmental protection

Auto-feeder:

1. 50 ton hydraulic pressure help feeding more raw materials.

2. The diameter is 1.4m. It can feed all kinds of raw materials, including plastic, packages of plastic, truck tire,

car tire, or tire pieces after cutting.

3. Save labor, save time.

4. After finishing production it can feed raw material instead of waiting the reactor to be cooled.