Continuous Tyre Pyrolysis Plant

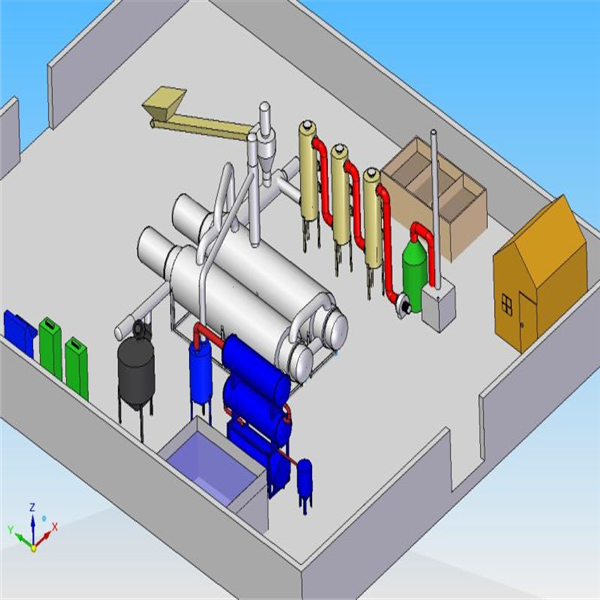

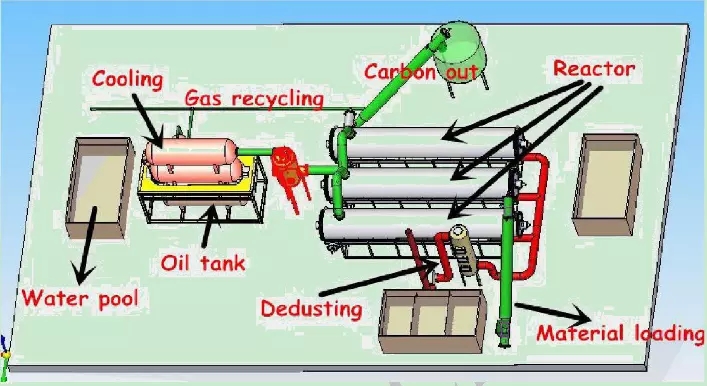

Continuous Tyre Pyrolysis Plant is controlled automatic mode from the operator’s touch screen. Process data is controlled and monitored by various instruments and a control system. Safety interlock system monitoring deviations from main process parameters ensures the plant’s safe operation and long life. The plant is supplied with air cooling system that cools media (cooling water). Continuous Tyre Pyrolysis Plant include the following assemblies: pyrolysis assembly, condensation assembly, control system equipped with safe start devices.

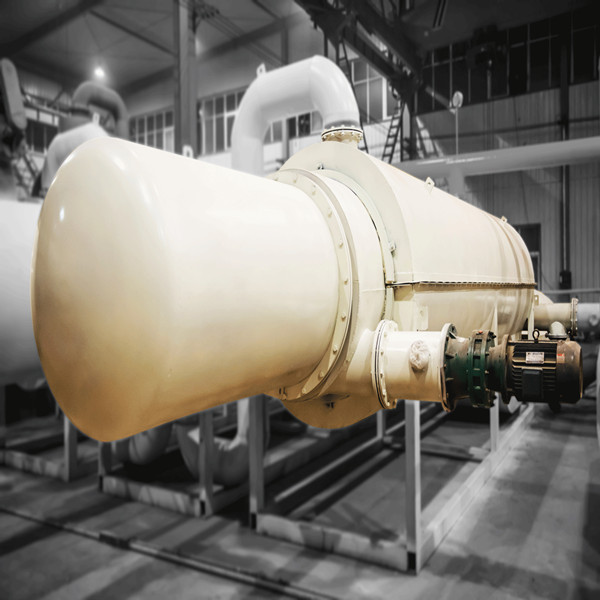

Reactor adopt anti-coking solution, totally different from other China manufacturer, no dust adhering on the wall.

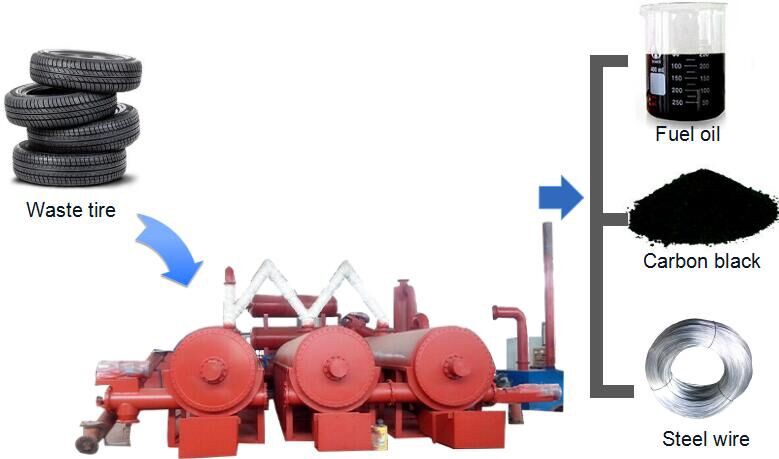

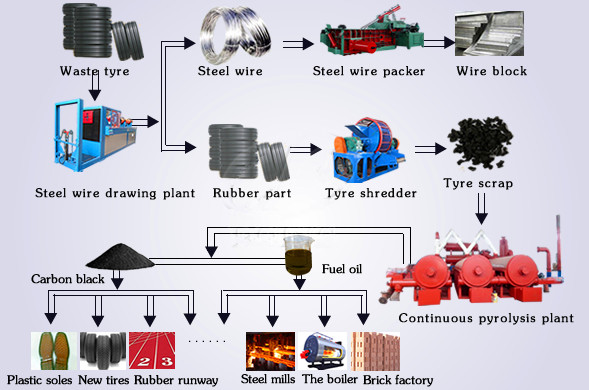

To keep continuous feeding and discharge system, it requires the waste tires should be in small size. So before continuous pyrolysis process, the waste tyres should be shredded into small pieces. And to avoid the steel wire mix with carbon black after pyrolysis process which is difficult to separate, it’s better to remove the steel wire from waste tyres at first.

Working Process

Continuous waste tyre pyrolysis plant ant is equipped with automatic feeding and discharging system, which can realize

feeding materials on one side and discharging slag continuously from the other side. Besides, it not only can dispose

30-100 tons waste tyres/plastic per day but also can work continuously for 24 hours without a stop

.As for detailed process, please check as below:

1. Collect waste tyres: All kinds of waste tires are available, from small car tires to big OTR tires.

2. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tires.The steel wire pulling machine is operated automatically, which only need one work for operation.

3. Shred tires: Use a specialized tire shredder to process big whole tires into 3-5cm small pieces for easy feeding. The tire shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

4. Continuous pyrolysis process: Shredded tires go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tires to the carbon black dischrge system for discharge.

Specification

| Technical data | Continuous Tyre Pyrolysis Plant |

| Capacity | 30TPD, 50TPD |

| Voltage | 380V/50hz |

| Electric power consumption | 11KW |

| Alternative fuel type for startup | Natural gas/heavy fuel oil |

| Heavy fuel oil | 800kg/Day |

| Lead time | 45Days |

| Plant minimum area occupied | 32 meters length, 15 meters width, 10 meters height |

| Condensation assembly weight | 7±5% tons |

| Pyrolysis reactor weight | 40±5% tons |

| Pyrolysis reactor diameter | 1700 mm |

| Maximum temperature of oil gas | 200 ℃ |

| Cooling media type and its temperature at the inlet of the HX | Cooling water no more than 40 ℃ |

| Required utilities | Initial cooling water supply Electric power supply |

Advantage

1.Fully automatic with low labour cost

Our continuous waste plastic pyrolysis plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2.Fully pyrolysis for high oil output

Our continuous waste plastic pyrolysis plant adopts mutiple reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

3.Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tyre pyrolysis plant can process at least 10 tons waste tires per day, up to 100T/D.

4.Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous waste tyre pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5.Continuous working save time and energy

6.Long working life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor.