Project Details

working process

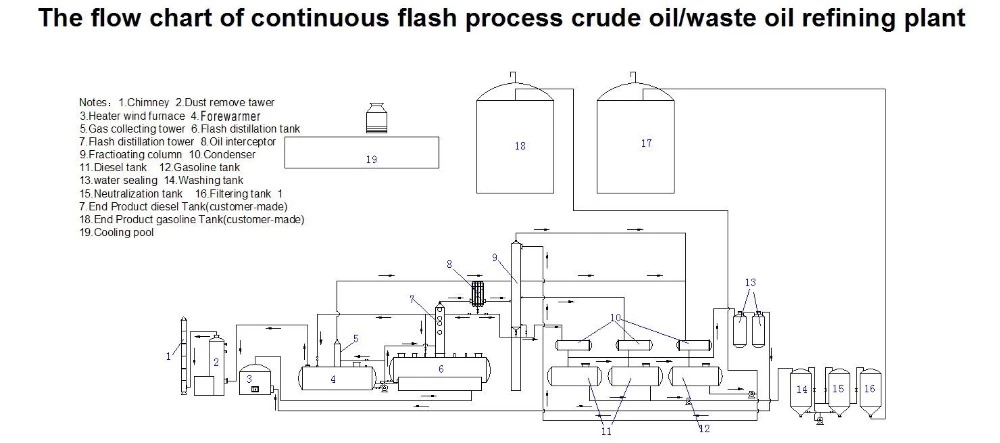

First,the oil sluge goes into the two pretreament oil tanks to get flocculation and sedimentation treatment. Add flocculant to one of the tank then mix the oil with air flow. Then pump the oil to the distillation reactor to heat the oil to 60℃. Then close the valve of tank A, the oil in tank A starts its will flocculent settling.

5 hours later,after the flocculant has settled down,drove out the flocculant and put it to the pretreatment oil tank B. Repeat the steps of tank A. The flocculant can be used for more than ten times and there will be no pollution of this. While the oil in tank B getting precipitated,the oil in tank A could be distillated in the evaporation machine . The oil would get heated in the pipes of the distillation reactor and be pumped to the evaporation machine again and again.

Oil turned into oil gas in the evaporation machine, and be sucked to the condenser after the supply machine which can separate the light oil gas . We can also get a little lightest oil in the tiny tank under the supply machine. This part of oil could be used in motor bikes,but this part is pretty little. Oil gas becomes refined fuel after cooling and will be pumped into the temporary oil tank to get next cooling.

The whole plant is working with micro negative pressure, which is provided by the vacuum pump. The smoke of the whole progress will get purged by the stormization sulphur dust collector.

Specification | |

Capacity | 3 T , 5 T, 10 T, 30 T ... |

Working type | batch type and contnuous type |

Avaiable raw material | Pyrolysis oil ,used motor oil , furnace oil , mixed waste oil , hydrulic oil , sludge oil etc. |

Heating fuel | coal , wood , pyrolysis oil , natural gas |

Reactor raw material | Q245R steel plate , Q345R boiler steel plate or customized support |

Machine landing area | 300-400 square meter (various by different capacity) |

Operators | 2 workers per shift |

Features of distillation equipment

1.Continuous producing, low cost

Oil extraction rate is about 90%, reformer 100%, high efficiency, high profits

2. High oil quality, most of index can can reach government standard of oil quality technique

3. New thermal insulation material, better effect

4. Condenser recycling cooling, easy to clean

Waste gas recycling system, saving fuel and avoiding secondary pollution

Output product data

No. | End Production Name | oil yield | Usage |

1 | Diesel fuel | 85% | Used for diesel engines like trucks , tractors , ships ,power generators etc. |

2 | Residue oil | 9% | used for distillation machine as heating fuel |

3 | Syngas & impurities | about 6% | Recycled to distillation furnace as heating material |

Collecting oil from the distillation machine, the yellow color oil is diesel oil after remove color and smell.

Successfull Installation