Plastic pyrolysis involves subjecting plastic to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Pyrolysis is great a way of recycling waste plastics.

|

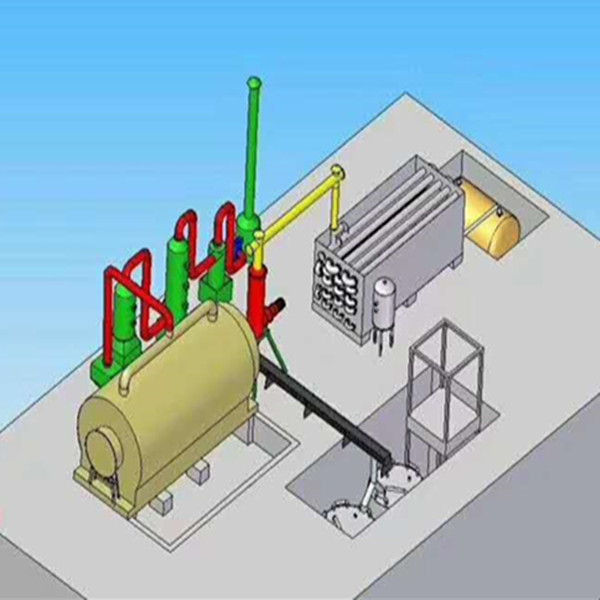

Waste Plastic Pyrolysis Plant is an ideal equipment used for recycling waste plastics. It adopts the latest pyrolysis technology by which plastics can be fully converted into useful resources(Plastic Oil and Carbon Black).

Final Products And Application

Final Products of Plastic Pyrolysis Plant include Plastic Oil and Carbon Black,The plastic oil can be widely used as fuel oil in many industries and can also be refined to diesel oil. The carbon black can be used for making construction bricks with clay or used as fuel. By the extra gas recycling system, the combustible gas will be recycled to heat the reactor as fuel, which will save energy for the whole recycling process of plastic.

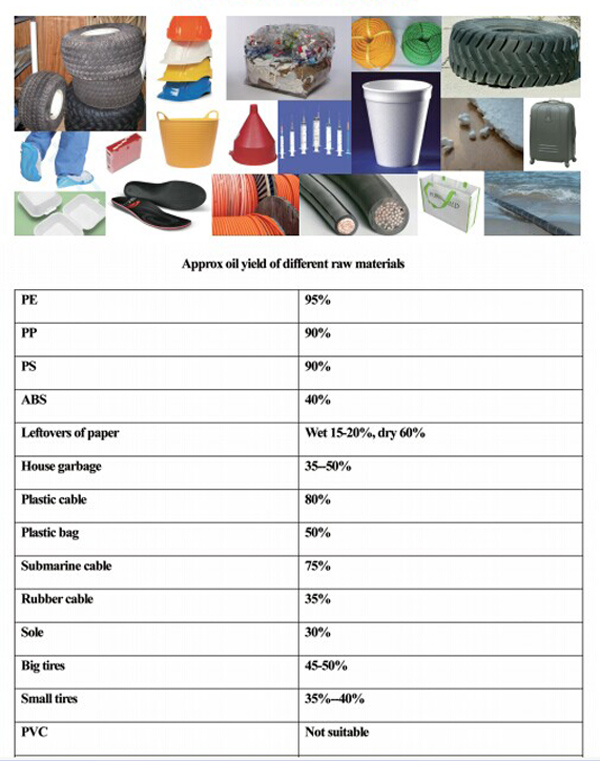

Raw Material

Plastic Pyrolysis Plant is suitable for Waste Plastics(include all kinds of Waste plastics), Such as waste acrylic (PMMA), PE (price is high, generally used to make plastic particles), PET (transparent bottles, try not to use), PVC, PP( disposable cups, try not to use) and all kinds of waste nylon products.

Production Process

The pyrolysis process of Plastic Pyrolysis Plant is very simple and easy to understand. It refers to the thermal decomposition of waste plastics at high temperature in the absence of oxygen. Totally sealed design can guarantee the whole process is very environment friendly. When the process is finished, we can get plastic oil, carbon black and a little combustible gas. And all the end products have a wide range of applications.

Technology Characteristics

1.Environmental protection: It is through the flue cooler and spray dust removal system to dedust. More than 95% of the dust would be remove.

2.Energy saving: In the process of Waste Plastic to Oil Plant, some combustible gas can not be converted into oil liquid in normal temperature and pressure, which could be recycled to the bottom of the reactor for reheating through the pipe of tail gas. In this way, it can avoid the gas contamination and save the fuel energy.

3.High-efficiency: The structure of reactor for the pyrolysis process is 360-degree rotating. This special design makes the bottom of reactor heat evenly, which lengthen the service life of reactor as well as improve the pyrolysis speed.

Since different waste plastics prices are different in the market, the benefits that can be obtained with different waste plastics are also different. Based on many years of the industry experience, we have summarized the oil yield of different waste plastics for your reference.