Various suitable waste raw material for pyrolysis machine

Raw material: waste tires , waste plastic , pp , pe , ps , abs , PMMA /acrylic scrap , aluminum scrap .oil sludge , drilling mud

Waste tyre Pyrolysis Plant is applied for recycling waste tire, waste plastic, waste rubber to fuel oil. According to the actual situation in every country and district, we developed different models of Batch Pyrolysis Plants for waste tires, rubber and plastic with daily capacity 5 -10 tons.

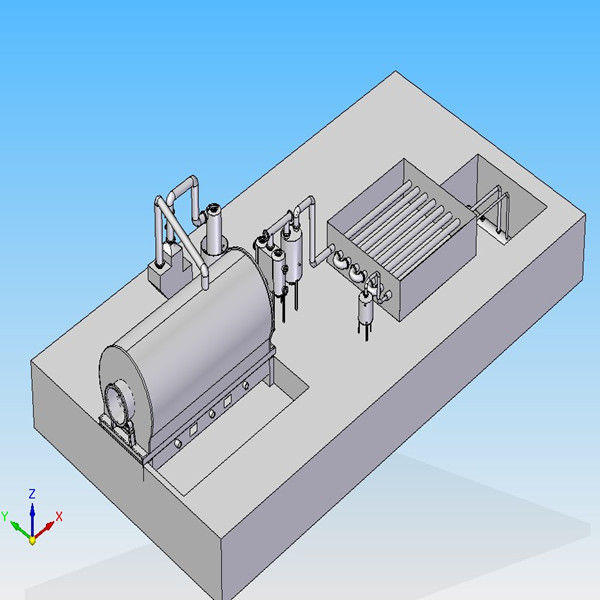

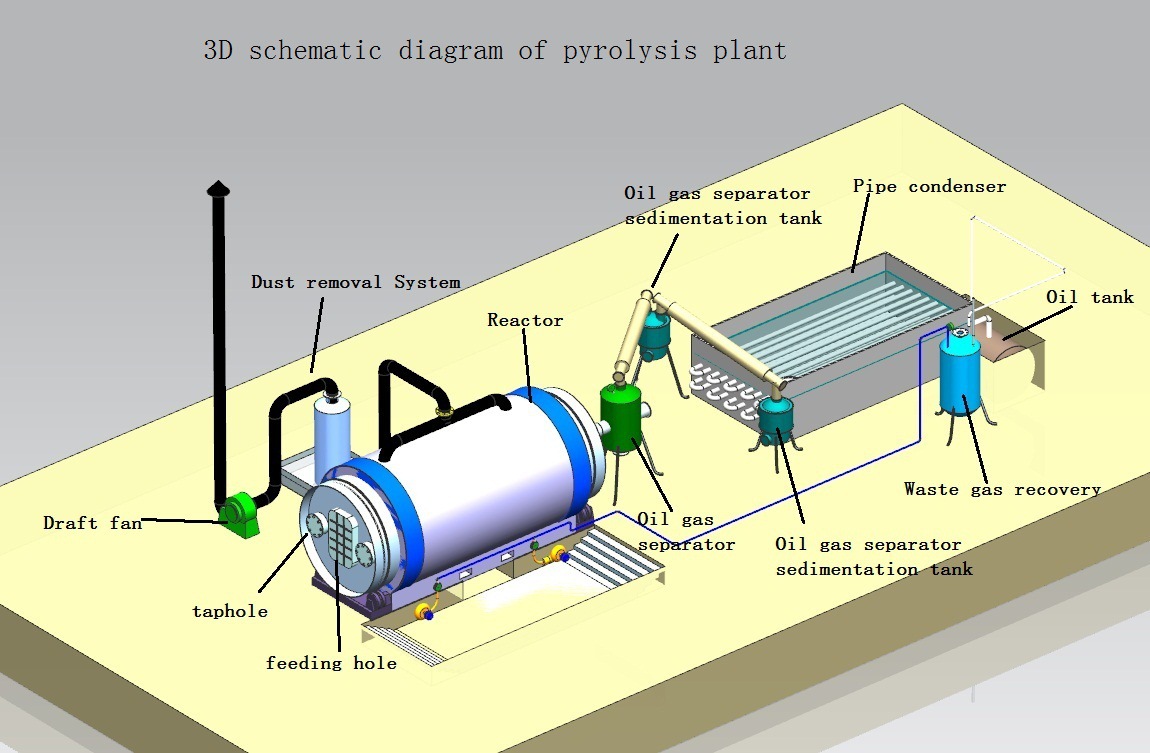

Technological Process

1.Tyre transported to reactor to pyrolyze.

2.Oil and gas from pyrolysis go into gas-liquid separating tower and separate, and enter into condenser to liquify , to get fuel oil, then enter into oil storage tank.

3.Coarse carbon black and steel wire from pyrolysis are output by automatic slag remover, transported to carbon black processing system by cooling hoist.

Separate steel wire and carbon black through the magnetic separator,to get industrial carbon black and steel wire.

4. Steel wire pulled out by winch, compressed into pieces, and do steel scrap process.

5. Flammable gas enter into waste gas tank and processed. Then extracted by vacuum pump, enter into water sealed tank and send to hot air furnace to burn.

| Main Parts for Pyrolysis Plant | |||||

| No. | Name | No. | Name | No. | Name |

| 1 | Pyrolysis Reactor | 6 | Water Seal | 11 | Air Blower |

| 2 | Air Blower | 7 | Draft Fan | 12 | Controller |

| 3 | Damping Tank | 8 | Reducer | 13 | Reactor Carrier |

| 4 | Cooling System | 9 | Desulfurization and Dust Removal System | 14 | Tubes &Pipe Fittings |

| 5 | Oil Tank | 10 | Gas Injection Lance | 15 | Other Parts |

Specification

Item | Detail | Detail | Detail | |

Type | JZ-05 | JZ-08 | JZ-10 | JZ-12 |

Raw material | Waste tyre, plastic, | Waste tyre, plastic, | Waste tyre, plastic, | Waste tyre, plastic, |

Capacity/day | 5t | 8t | 10t | 12t |

Inlet diameter | 1200mm | 1200mm | 1200mm | 1200mm |

working | Batch-tyre | Batch-tyre | Batch-tyre | Batch-tyre |

Covering area | 150 | 160 | 180 | 200 |

Oil yield | 45%-50% | 45%-50% | 45%-50% | 45%-50% |

Labor force | 2-3 | 2-3 | 2-3 | 2-3 |

Reactor size | D2200mm*L5000mm | D2200mm*L5000mm | D2200mm*L5000mm | D2200mm*L5000mm |

Noise | ≤85dB | ≤85dB | ≤85dB | ≤85dB |

Type ofcooling | Water-cooling | Water-cooling | Water-cooling | Water-cooling |

weight | 24t | 28t | 31t | 33t |

Running time | 14-16h | 14-16h | 14-16h | 14-16h |

Fuel | Charcoal,wood, | Charcoal,wood, | Charcoal,wood, | Charcoal,wood, |

Carbon | Slagging | Slagging | Slagging | Slagging |

Catalyst | No needed | No needed | No needed | No needed |

Factory required

Working Power | 15-30KW ( Varies by Design and Capacity) | ||

Area Cover | 300 square meters (L*W*H= 30M*10M*7M) | ||

Labor need | 2-4 persons( Varies by Configurations) | ||

Processing Time | Loading 2 hours, Processing 8-9 hours, Discharge carbon and steel 1.5 hour (Take 12 tons/day as sample) | ||

Applicable Material | Waste tyre, Waste Rubber, Waste Plastic, all kinds of oil sludge, waste aluminiu, foil, electric cable, Waste Leather Offcut, Waste Acrylic(PMMA), etc... | ||

Heating fuel | Pyrolysis Oil, Natural Gas, Electric , Coal, Firewood . | ||

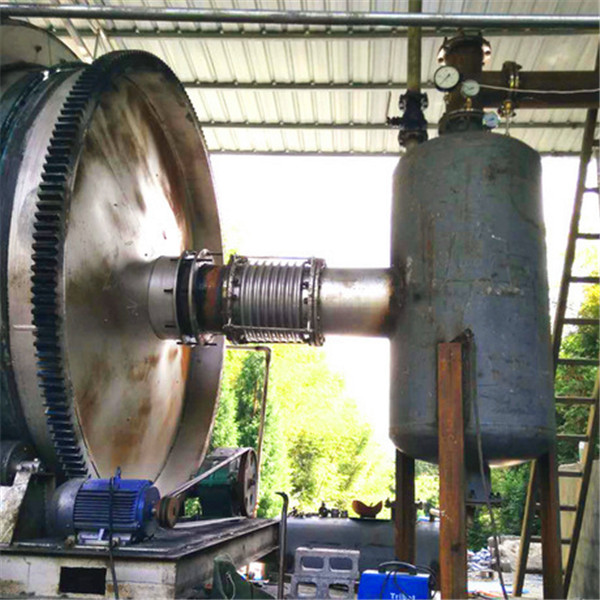

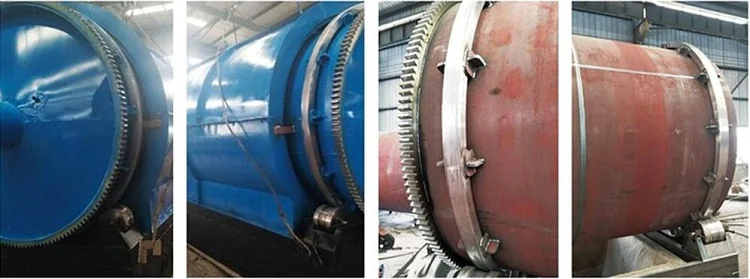

Reactor:

1. The gear can be seperated from reactor, instead of welding on reactor. So it will not be destroyed by cycling heating.

and very easily to be re-placed

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q245R/ Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

Oil separator:

1. Water from raw material will be separated here.

2. Water sealing design prevent tempering. Ensure saftety.

3. Heavy oil will be collected here.

Cooling system :

1. Coil pipe cooling system : there are 22-30 pipes lied in the water pond,each pipe 6 meters long, oil gas can be cooled in larger area and longer time,thus get higher oil yield .

2. Vertical condensrs : we supply 4 cndensors, each has 44 pipes inside the condensors. Save land and looks more neat and beautiful.

Anti-back fire device:

1. Little residual gas can not be cooled. It will recycle these gas to furnace burned to heat the reactor.

2. Water sealing disign will prevent tempering. Ensure safety.

Double dust removal device:

1. Dispose of flue gas caused by heating reactor using coal, wood, oil or natual gas.

2. Environment protection.

Safety system:

1. Auto welding to improve working efficient, ensure machine quality, avoid accident.

2. Special design to avoid the jam with X-ray test, ensure safety running.

3. Vacuum system ensures the whole line working well.

Environmental protection:

1. Dust and sulfur removal system remove smoke and sulfur.

2. The exhaust gas (include methane to butane) will be directly recycled to furnace for fuel, no gas pollution.

High oil yield:

1. Three cooling processes ensure the oil gas liquefied sufficiently.

2. Catalyst chamber ensure the raw material pyrolysis totally.

Long service life:

1. Special boiler plate:Q245R with 16mm thickness.

2. Auto welding to ensure the machine life, service life will be 8-10years.

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

High profit

Feasibility Analysis Report of scrap tyres to oil equipment | |||

1set 5 ton capacity machine as sample | |||

NO. | Iterm | Cost of per batch | |

1 | Dynamic | a.oil pump | 4.5kw*4h*1=18RMB |

b.air pump | 3kw*10h*1=30RMB | ||

c.water pump | 2.2kw*60h*1=132RMB | ||

d.draft fans | 4kw*72h*1=288RMB | ||

e.fuel 500kg-800kg(5000Kcal-6500Kcal) | 4* 16.3$= 65.2$ | ||

total cost | 1168RMB | ||

2 | Catalyst | 600 RMB | |

3 | Manpower | 3person*3 days | 900RMB |

4 | Waste plastic& Tyre oil | 3500RMB/Ton | |

5 | Outputs | Final Product oil90%-92% | 27600RMB |

6 | Profits | 27600-3500RMB*5Ton-2668=7432RMB/Batch | |

Remark: Handle one ton oil cost: 500RMB/Ton,Convert RMB into USD82/Ton. | |||

Installation

Take waste tyre as example, its final product as follows:

No. | Item | Ratio | Usage |

1 | Pyrolysis oil | 40%-45% | can be sell directly to boiler factory , steel factory , cement factory , power plants , glass factory etc. |

2 | Carbon black | 30%-35% | can be sell directly. |

3 | Steel wire | 15% | can be sold directly. |

4 | Non-condensible gas | 10% | can be returned to furnace to second burning. |