NO. | Raw material | Note |

1 | Waste tyre | Steel tyre ,Nylon tyre ,Bick tyre |

2 | Waste plastic | PE,PVC,Waste washed mixture plastic from waste Paper Factory |

3 | Waste rubber | Shoes Soles,Cable Skin |

4 | oil sludge,waste oil sludge |

NO. | Fuel |

1 | Oil(fuel oil, tyre oil, heavy oil etc..) |

2 | Natural gas |

3 | Coal |

4 | Firewood |

5 | Carbon black pellet |

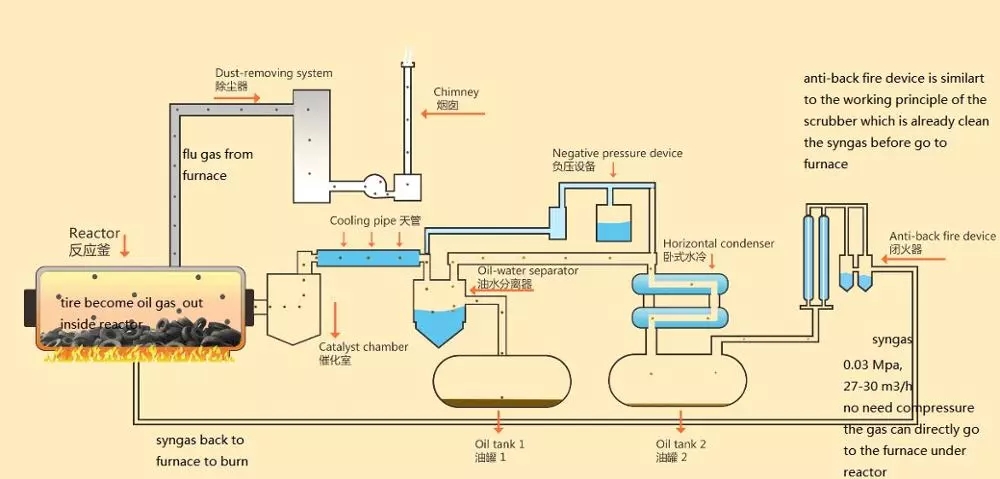

The flow process of Batch Pyrolysis Machine

Characteristics

1. High oil output rate 45%--55% with special catalyst formula and high tech.

2. Rapid condensers and large cooling area,assure you get much more and higher quality oil. diversiform cooling system (condensers or pipe pond) can be choose according to client's willingnes.

3. Dust-removing device -four levels dust processing system make sure no any population and the output smoking is the spray .more environmental protection,no-pollution.

4. Double tail-gas recycling and burning system,saving energy.

5. Q245R boiler plate, high temperature resistance, thickness reaches 16mm, guarantee 4-7 years service lives. and optional plate is Q345R.

Technical parameters

Equipment’s model | JZ-10 |

Raw material | Waste rubbers/tyres/plastic |

Structure Form | Horizontal type |

Daily Handling capacity | 10 tons |

Working pressure | Normal pressure |

Main engine rotating speed | 0.4R /min |

Equipped power | 3KW |

Cooling Mode | Water |

Floor Area | 180m2 |

Heating Mode | Direct |

Oil Yield | 45%-50% |

Noise dB (A) | <=85 |

Machine dimension(mm) | D2600*L6600 |

Working Mode | Intermittence |

Safety

1) Auto welding, X-ray detection room is special for welding seam

2) 2 alarms+ 3 safety valves+ 2 temperature gauges+ 2 pressure gauges= security system

3) Water seal shall prevent backfire and special design can reduce corrosion to reactor

4) Waste flammable gas reheat the reactor, guarantee safety

Energy Saving

1) The whole reactor can be heated, so the raw material can be fully pyrolysised

2) Fire road is designed as spiral, fuel shall be fully burned

3) Need no circulating water, save electricity power

4) Special design for gas separate to seep up pyrolysis process

High profit

1) 70% light oil, 30% heavy oil

2) The oil you get without water

3) pyrolysis machine Feasibility Analysis Report

Feasibility Analysis Report 10 tons | ||

NO. | Item | Cost of per batch |

1 | 10 tons of waste tire | 10T* 260$/T= 2,600$ |

2 | 0.3 tons of coal | 0.3* 97.6$/T= 29.28$ |

3 | water | 0.4$ |

4 | electricity | 15.6$ |

5 | workers | 4* 16.3$= 65.2$ |

total cost | 2710.48$ | |

NO. | Item | Income |

1 | Crude oil (40%-45%) | 10T* 40%* 715.5$/T= 2,862$ |

2 | Carbon black (30%-35) | 10T* 30%* 73$/T= 219$ |

3 | Steel wire (10%-15%) | 10T* 10%* 300$/T= 300$ |

4 | Gross profit | 3,381$ |

5 | Daily net profit | 3381$-2710.48$=670.52 |

6 | Monthly net profit | 670.52$*25days=16,763$ |

7 | Yearly net profit | 16,763$*10months=167,630$ |

Cooperation

End product percentage and useage( Example : raw material is tyre)